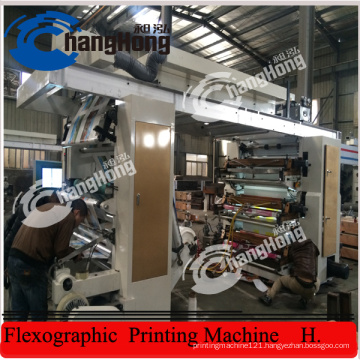

4color Aluminum Foil Laminator Paper Flexo Printing Machine (CH884-1400L)

Basic Info

Model No.: CH884-1400L

Product Description

Model NO.: CH884-1400L Printing Color: 6 Colors Dryer: Electric Heating Embossing Structure: Rotary Letterpress Application: Flexible Packaging Printing Printing Speed: 10-70m/Min Double Side Print Color: 4+0, 3+1, 2+2 Tension: Automatic Tension Controller Printing Roller Lift up and Down: by Automatic Hydraulic Trademark: Changhong Specification: 600-2200mm, at your choice HS Code: 84431600 Printing Page: Double Faced Anilox Roller: Ceramic Anilox Roller Type: Flexographic Structure: Stacked Automatic Grade: Semi-Automatic Singel Side Print Color: 4color Roller: Steel or Ceramic Anilox Roller EPC: Auto EPC Normal Print Speed: 10-70m/Min Transport Package: Film, Then Use Wooden Pallet Sea Safety Packages Origin: Ruian City, Zhejiang Province of China 4color Aluminum Foil Laminator Paper Flexo Printing Machine (CH884-1400L)

Changhong Machinery Company is mainly engaged in design and manufacturing of printing machines. It is capable of independently developing new flexographic printing machines.

Machinery products developed in the recent years, we have many kinds machine, such as normal-speed 10-60m/min, Middle-speed 10-100m/min, , high-speed over 120m/min standards.

The products of Changhong mainly feature stable and simple operation, good durability, simple maintenance, even inking, strong stability and long service life.

If need any video or data about our machine, pls contact Holiday : 0086-18857728175!

1. The main features:

1. Take it easy, accurate color, long life.

2. Use motors, variable frequency speed control, saving electricity, small running fluctuations.

3. Off printing roll automatic stop the ink-running motor, and up-printing roll automatic start running the ink.

4. Use special diagonal-tooth gear, accurate printing size.

5. Two sets of heating devices, including central heating and constant temperature control system for group control.

6. Low-roller special steel processing, and special process, and plating thickness of 0.1mm protective layer of hard chromium.

7 Alloy roll with hard oxidation, treating by dynamic balance, static balanced.

8 With cold wind bellows, and can effectively prevent produce with ink adhesion after printing

9. Print produce are clear and good arrangement quality.

10. Bearing: NSK, Japan Brand, Germany ASNU aluminum alloy roll

2. Machine process:

Unwinding unit-----auto tension controller for unwind ------EPC for correct position ---------Flexo printing -----------Heating and drying -------Rewinding Unit

3. Machine different requires:

1) machine width require:

Standard: 600, 800, 1000, 1200, 1400, 1600mm

Special: 1800, 2000, 2200, 2400m, 3200mm etc.

2) machine speed require:

Standard / normal speed: 10-60m/min

Middle speed: 10-90m/min

High speed: 10-130m/min

3) machine printing material require:

Standard: For plastic film, PE, PP, OPP, HDPE, LDPE, etc. And 30-150gsm paper

Standard 2: Only for paper, 50-350gsm

Standard 3: Only for non woven material

Special: For alumnium foil, pp woven bag etc.

If you want to talk further about machine you require, pls contact Holiday : 0086-18857728175!

Contact us if you need more details on Laminator Paper Flexo Printing Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about 4 Color Printing Machine、Flexographic Printing Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Changhong Machinery Company is mainly engaged in design and manufacturing of printing machines. It is capable of independently developing new flexographic printing machines.

Machinery products developed in the recent years, we have many kinds machine, such as normal-speed 10-60m/min, Middle-speed 10-100m/min, , high-speed over 120m/min standards.

The products of Changhong mainly feature stable and simple operation, good durability, simple maintenance, even inking, strong stability and long service life.

If need any video or data about our machine, pls contact Holiday : 0086-18857728175!

1. The main features:

1. Take it easy, accurate color, long life.

2. Use motors, variable frequency speed control, saving electricity, small running fluctuations.

3. Off printing roll automatic stop the ink-running motor, and up-printing roll automatic start running the ink.

4. Use special diagonal-tooth gear, accurate printing size.

5. Two sets of heating devices, including central heating and constant temperature control system for group control.

6. Low-roller special steel processing, and special process, and plating thickness of 0.1mm protective layer of hard chromium.

7 Alloy roll with hard oxidation, treating by dynamic balance, static balanced.

8 With cold wind bellows, and can effectively prevent produce with ink adhesion after printing

9. Print produce are clear and good arrangement quality.

10. Bearing: NSK, Japan Brand, Germany ASNU aluminum alloy roll

2. Machine process:

Unwinding unit-----auto tension controller for unwind ------EPC for correct position ---------Flexo printing -----------Heating and drying -------Rewinding Unit

3. Machine different requires:

1) machine width require:

Standard: 600, 800, 1000, 1200, 1400, 1600mm

Special: 1800, 2000, 2200, 2400m, 3200mm etc.

2) machine speed require:

Standard / normal speed: 10-60m/min

Middle speed: 10-90m/min

High speed: 10-130m/min

3) machine printing material require:

Standard: For plastic film, PE, PP, OPP, HDPE, LDPE, etc. And 30-150gsm paper

Standard 2: Only for paper, 50-350gsm

Standard 3: Only for non woven material

Special: For alumnium foil, pp woven bag etc.

If you want to talk further about machine you require, pls contact Holiday : 0086-18857728175!

| Model | CH884-1400 L |

| Max. print material width | 1450mm |

| Printing width | 1360mm |

| Printing material | Aluminum Foil material |

| Printing color | 4 color (4+0, 3+1, 2+2) |

| Printing length | 7.5"~40"(190mm~1000mm) |

| M e ch a nical speed | 90m/min |

| Printing speed | 1 0m- 7 0m/min |

| Register precision | Longitude:±0.25mm Transverse:±0.25mm |

| Rewinder/Unwinder DIA | Φ 8 00mm |

| Printing plate lifting system | Auto Hydraulic cylinder control printing roll up and down |

| EPC system: | Edge Position Controller, 1 PC |

| Tension system | Automatic tension control for unwinding and rewinding, 2PCS |

| Unwinding loading and rewinding unloading way | By air shaft , with 5kg magnetic 2 pcs With 1.5 kw motor compages rewinding |

| Printing Pressure | M echanical adjust |

| Anilxo roll | Ceramic anilox roller ( 3 00-800lpi), single doctor blade |

| Master motor | 3.7Kw TAIWAN BRAND |

| Drying way | Electrical heat drying |

| Drying power | 20 kw (it is special with double surface blowing ,wind cooling circulate, drying fast,also with high speed drying for fastness , with 2set |

| Blower of nature wind | 1.5 Kw x2pcs 75kw x 4 pcs |

| Inking motor | Taiwan brand |

| Master frequency converter | 3.7 kw |

| Master power | 28 Kw |

| Dimension(L×W×H) | 4.8 ×2. 8 × 2.6m |

Product Categories : Flexographic Alum Foil Printing Machine

Other Products

Hot Products

Cheap Laser Acrylic Cutter Syngood SG6090 for Wood/Acrylic/PaperSyngood Fiber Laser Marking Machine SG10F/SG20F/SG30F-Special for dog tagPortable Easy operation Syngood mini desktop cnc router for 4 axis cncOne time finish Milling Engraving Cutting no need operator SG1325 ATC -atc spindle cnc routerMetal Engraving Machine SG4040Big Woodworking Wood Furniture for SG 2.0*3.0m Router CNCBig Woodworking SG 2.0*3.0m CNC RouterWooddoor Make CNC Router 1.3*2.5mSyngood SG5030-35W 500*300mm Laser Engraving Machinecnc yag laser cutting machine YAG LASER MACHINE FOR CUTTING METAL Syngood SG0505(0.5*0.5m ) Stable YagPortable stone laser engraving machine 600*900mm with photo engravingCO2 Metal None-metal Laser Cutting Machine S.S. 1.5mm None metal Acrylic 30mm Wood 23mm 150W 1300*2500mmMDF Wood Die Board cutting machinery 300W 400W laser tube 18mm 22mm 23mm for MDF20mm Fiber Laser Cutting Machine for Metal 500w 750w 2000w 3000w for Stainless Steel304 401 ,Carbon Steel,AluminumTwin Head Roll to Roll Laser Engraving Machine Syngood 1300X2500mm 1500x3000mm 1800x1200mm 1800x3000mmWood Laser Cutting Machines Syngood 600*900mm for 8mm thickness well cutting